The Manufacturing Process of Sugarcane Bagasse Tableware in India

Sugarcane bagasse is the fibrous byproduct left after extracting juice from sugarcane. Instead of being discarded or burned, this biodegradable material is increasingly being used in India to manufacture eco-friendly, disposable tableware. Here’s a step-by-step guide to how these sustainable products are made:

1. Raw Material Collection

Source: Sugar mills supply sugarcane bagasse after juice extraction.

Initial Processing: The raw bagasse is sun-dried or mechanically dried to reduce moisture content and improve storage stability.

2. Cleaning & Pulping

Cleaning: The dried bagasse is cleaned to remove impurities like dirt, dust, or residual sugar.

Pulping: It is then ground into fine particles and mixed with water to form a pulp (similar to paper-making).

Optional Additives: Natural binders or strengthening agents (like starch) may be added, depending on the product specifications.

3. Pulp Molding

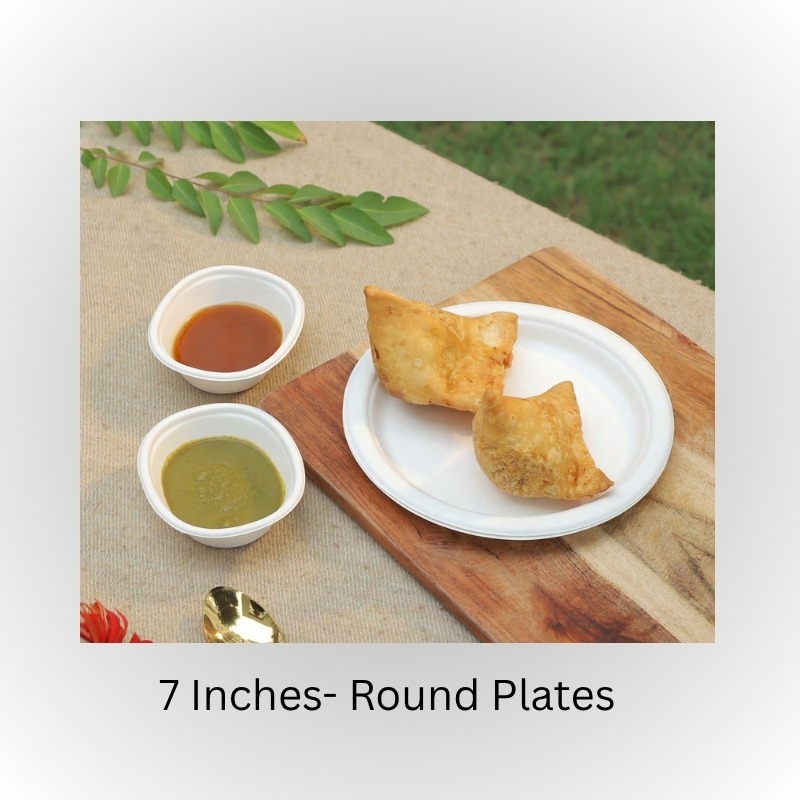

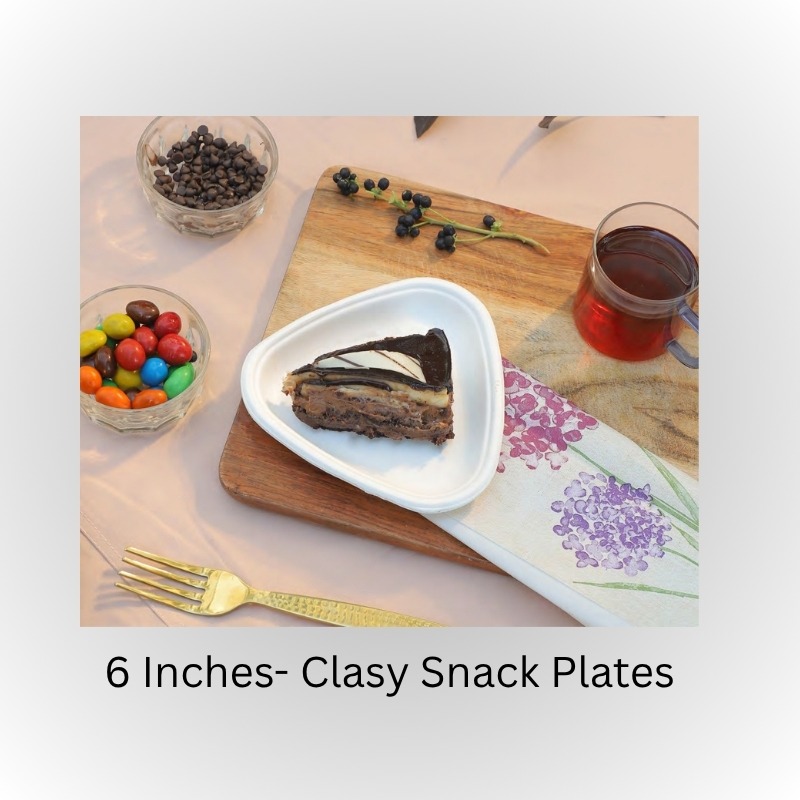

Mold Preparation: Stainless steel molds are designed for specific shapes (plates, bowls, trays, etc.).

Forming Process: The wet pulp is poured into heated molds under pressure.

Vacuum Suction: Water is removed by suction, leaving behind a shaped, semi-solid pulp.

4. Hot Pressing & Drying

Final Pressing: The mold is closed and heated again under high temperature and pressure (~180–200°C).

Drying & Curing: This solidifies the shape, removes remaining moisture, and enhances rigidity.

Demolding: The finished product is released from the mold.

5. Trimming & Finishing

Edge Trimming: Excess pulp or uneven edges are trimmed for clean finish.

Surface Treatment (Optional): Some products are coated with food-grade water or oil-resistant coatings to improve durability.

6. Quality Check

Inspection: Each item is inspected for strength, shape consistency, and surface smoothness.

Testing: Tests for water/oil resistance, temperature tolerance, and compostability may be performed.

7. Packaging & Distribution

Eco-Friendly Packing: Products are stacked and packed in recyclable or biodegradable packaging.

Shipping: Products are distributed across domestic and international markets, with rising demand from food chains, events, and retail.

✅ Key Features of Sugarcane Bagasse Tableware

100% compostable and biodegradable

Microwave & freezer safe

Oil and water resistant

Sturdy and lightweight

Sustainable alternative to plastic and Styrofoam

India’s Role in Global Supply

India, being one of the largest producers of sugarcane, has a massive supply of bagasse. Several manufacturers across Gujarat, Maharashtra, Tamil Nadu, and Uttar Pradesh have set up eco-tableware units to cater to both local and export markets (especially in Europe and North America).